When your wheel speed sensor, also referred to as the WSS, fails or you have issues with the sensor\’s wiring circuit, it will likely disable your ABS system, and in turn, triggering your ABS dash warning light. This is a severe problem. The ABS module must get accurate input from all sensors to properly establish whether a wheel is locking up or not.

How the Wheel Speed Sensor in the Antilock Brake System Works

The wheel speed sensors generate an AC, or alternating current, output voltage. This voltage varies in frequency and amplitude along with your wheel speed. The faster you go, the greater the frequency and amplitude. The signal’s strength may be adversely affected by resistance in the sensor, the wiring and connectors, metallic fragments that have found their way to the end of the sensor, or even the air gap that is between the sensor and tone ring found on your axle, hub, brake rotor, drum or CV joint.

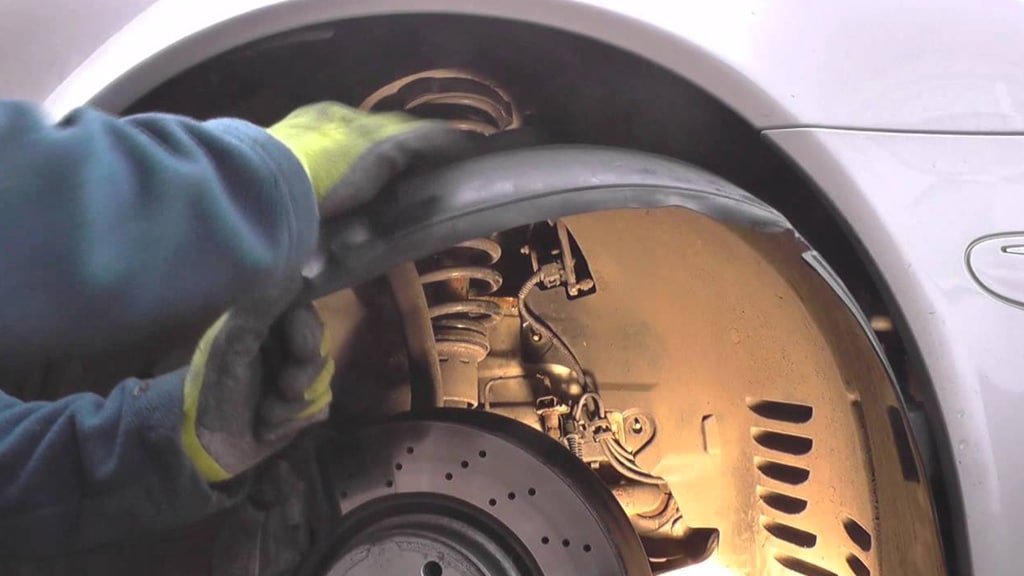

When your ABS dashboard warning light has come on, have an adjustable wheel speed sensor, and you get a code indicating a wheel speed sensor issue, the trouble may be as simple as having too wide an air gap. A slight air gap is usually required to create a strong enough signal within the magnetic windings of the sensor. Air gaps are usually in a range from .016 inches to as great as .050 inches (0.40 to 1.3 mm). You can use a nonmagnetic feeler gauge to set the gap to the recommended specifications.

Variations in the air gap could be sourced to bad wheel bearings or damaged, missing, chipped or broken teeth on a tone ring. Even minimal damage that may not be easily seen can sometimes be your problem.

Checking Your Wheel Speed Sensor

One way to check the wheel speed sensor is by measuring the output voltage. You can do this by plugging a breakout box into your ABS module\’s wiring harness. Using a digital volt ohm meter, or DVOM, attach the test leads to the appropriate pins for your WSS circuit.

An AC voltage of 50 to 700 MV with the wheel being turned by hand at about one revolution per second indicates a good wheel speed sensor. For exact voltage specifications consult your owner’s manual..

A low volt reading or no reading at all will require direct measurement of your resistance in the WSS circuit. This should be done with the key off, through the breakout box to adequately check your entire circuit. A wheel speed sensor that is good usually has a resistance of 800 to 1400 ohms. Again, you should consult your owner’s manual for the exact specifications for your particular vehicle.

If you find that you have too much resistance or it reads open or with little to no resistance, you need to measure the resistance across the sensor itself. If the reading is within specs, your problem will be in either your wiring or connectors. If it does not read within recommended specifications, you have a bad sensor that must be replaced.

If you need a scope test, you will need a professional mechanic. Bring your vehicle by Sanford’s Automotive Service in Columbia, SC for all of your automotive needs, foreign or domestic. We have proudly served Columbia and surrounding communities since 1989. Stop by today or call to make an appointment.